Over the last years, the complexity of vehicle systems has increased enormously, bringing along growing demands for environmental sustainability, safety, economy, and user-friendliness. Innovation needs to happen at shorter intervals for production timelines to stay the same. In working closely with our customers, it became clear to us that a framework like Automotive SPICE® is a highly beneficial addition to ensure quality-assured automotive software components.

Becoming A-SPICE certified was therefore a natural and exciting target for us. We have learned some things along the way, with several major takeaways identified.

Let’s look at some of the elements of A-SPICE in more detail.

A background to A-SPICE

As automotive systems become increasingly complex and data-driven, the challenge is how to properly develop a software-based solution, while facing shorter development cycles, increased complexity, and higher reliability expectations. This is what A-SPICE tries to solve, by establishing a framework that should enable and ensure a proper development process in an automotive systems development context.

Global standards exist for many aspects of automotive development, but there was no harmonized objective way to assess and plan improvements to automotive software development processes. A-SPICE fills that need, providing a framework and set of guidelines that, when applied properly, can ensure quality is delivered throughout the whole development process. This translates into a stronger basis for improved end-user safety and customer satisfaction.

At the same time, A-SPICE practices can help avoid mistakes during design, potentially saving costs as well as time to market. Because of how the A-SPICE practices function, testing, and production can work more closely together, improving the design process.

Compliance with A-SPICE is slowly but surely becoming a mandatory part of global automotive industry product development. Even as we speak, an extension of A-SPICE was published in 2019 covering the hardware development process. This means that all automotive suppliers will eventually face assessment for A-SPICE compliance. It is therefore wise to begin incorporating the practices of the framework early on.

The dimensions of A-SPICE

A-SPICE operates on two dimensions: process and maturity.

The process dimension

Derived from well-established software lifecycle process standards (such as ISO12207), the process dimension defines what needs to be done to properly produce a software module. It is important to note that it doesn’t tell how you should do it.

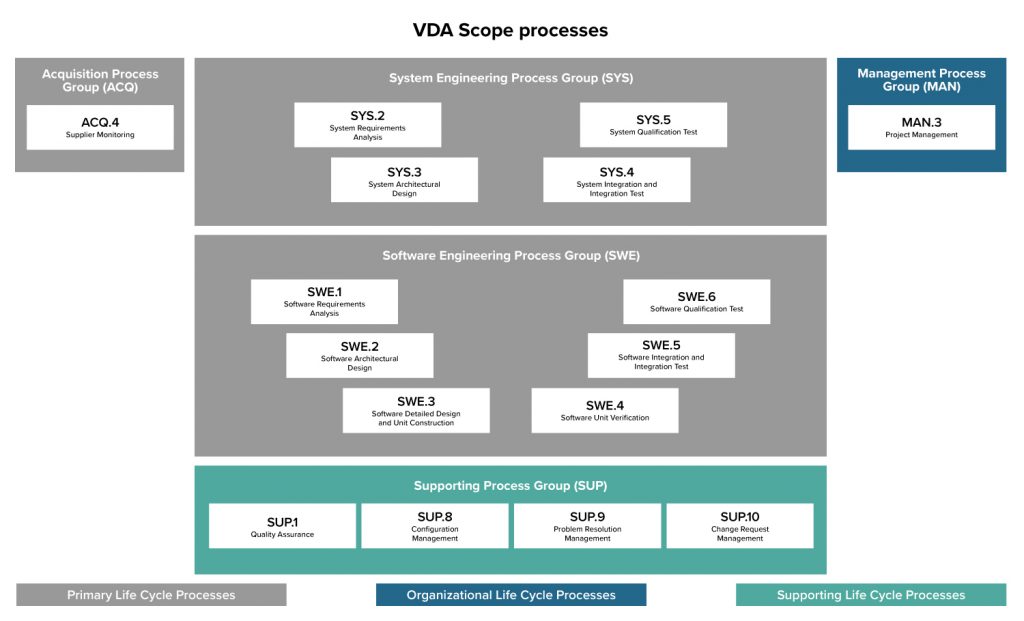

These dimensions consist of 32 processes (split into groups), which adapted for automotive needs is defined as the “VDA Scope”. These processes cover a comprehensive range of steps and areas in automotive software design that need to be handled for A-SPICE certification. Each of these processes includes a verification phase, ensuring that competency in each is carefully tracked and assessed.

The maturity dimension

This second dimension involves maturity or the so-called capability level. The processes defined in the VDA Scope are assessed, using ratings from 0 to 5 to indicate the level of process maturity:

0 – The process is incomplete or non-existent.

1 – Processes are in place and in use.

2 – Processes are in place, and you’re able to “manage them”, meaning monitor and track them.

3 – Processes are able to be “customized” for every single project done, and monitoring is kept under control.

4 – Outcomes are able to be predicted thanks to this level of process maturity.

5 – On top of the above, a continuous loop of improvement is added to all processes.

The learning curve: 3 aspects impacting successful implementation

It has been our observation that the main challenges in A-SPICE implementation involve requirements management, change management, and problem resolution, as well as traceability overall. With this in mind, successful implementation of A-SPICE on an organizational level is impacted by three key aspects that go hand-in-hand:

- Commitment from the entire organization.

- A proper tool both for managing activities and establishing traceability.

- Structured team-trainings.

In implementing Automotive SPICE, an initial hurdle encountered by an organization can simply be misunderstandings and wrong interpretations. These happen for a few reasons. Firstly, A-SPICE can be seen as adding a burden to operations, because an increase in documentation is needed throughout the whole process. This is the case from business acquisition all the way to final delivery.

Therefore, a mindset change may be required in order to be able to successfully implement A-SPICE.

To make that shift however, proper tools for data collection during the implementation journey are key. This is followed by using the data to inform decisions during implementation, like properly evaluating if the right things are being done correctly and in the right order. Furthermore, the data can help determine what to do when things don’t work as they should.

As the implementation process moves along, roadblocks can very quickly crop up if a proper understanding of A-SPICE processes and levels is missing. So at an organizational level, deciding to plan and implement formal trainings can be a critical addition. Doing so at Tuxera allowed for A-SPICE process features and needs to be simplified and translated into our own company “culture and language”. This laid the groundwork for more efficient, effective implementation of activities to fulfill all of the different A-SPICE process needs. Ignoring this step could, however, lead to overcomplicating some solutions while neglecting others.

Final thoughts

At this point, we expect to have Tuxera at level 2 of A-SPICE across the board by the end of the year (official assessments have been on hold due to Covid).

One can say that successful A-SPICE implementation is a balancing act between what is really needed and how it can be efficiently done in an organization. Having total commitment towards A-SPICE from all levels of your organization ensures the needed support system for implementation to work. Making use of tools and methods for tracking your own data throughout can serve to guide your team’s activities and avoid guesswork. Finally, formally training employees in A-SPICE processes can avoid overcomplication and painful mistakes.

Importantly, there’s no magic recipe. It takes time, constant learning, plus trial and error before getting it right.

Car makers and Tier-1 suppliers, see how we can make your automotive data handling and storage quality-assured and failsafe.

Jesus Cabrera

Jesus brings over 20 years of experience in automotive-related project management to Tuxera. As our Global Quality Manager, he leads implementation of global quality management systems, A-SPICE, and numerous other relevant standards in the Automotive industry, as well as quality in software development processes. Jesus is passionate about technology, project management, quality, the automotive industry, cycling, languages – and he loves working in an international environment.